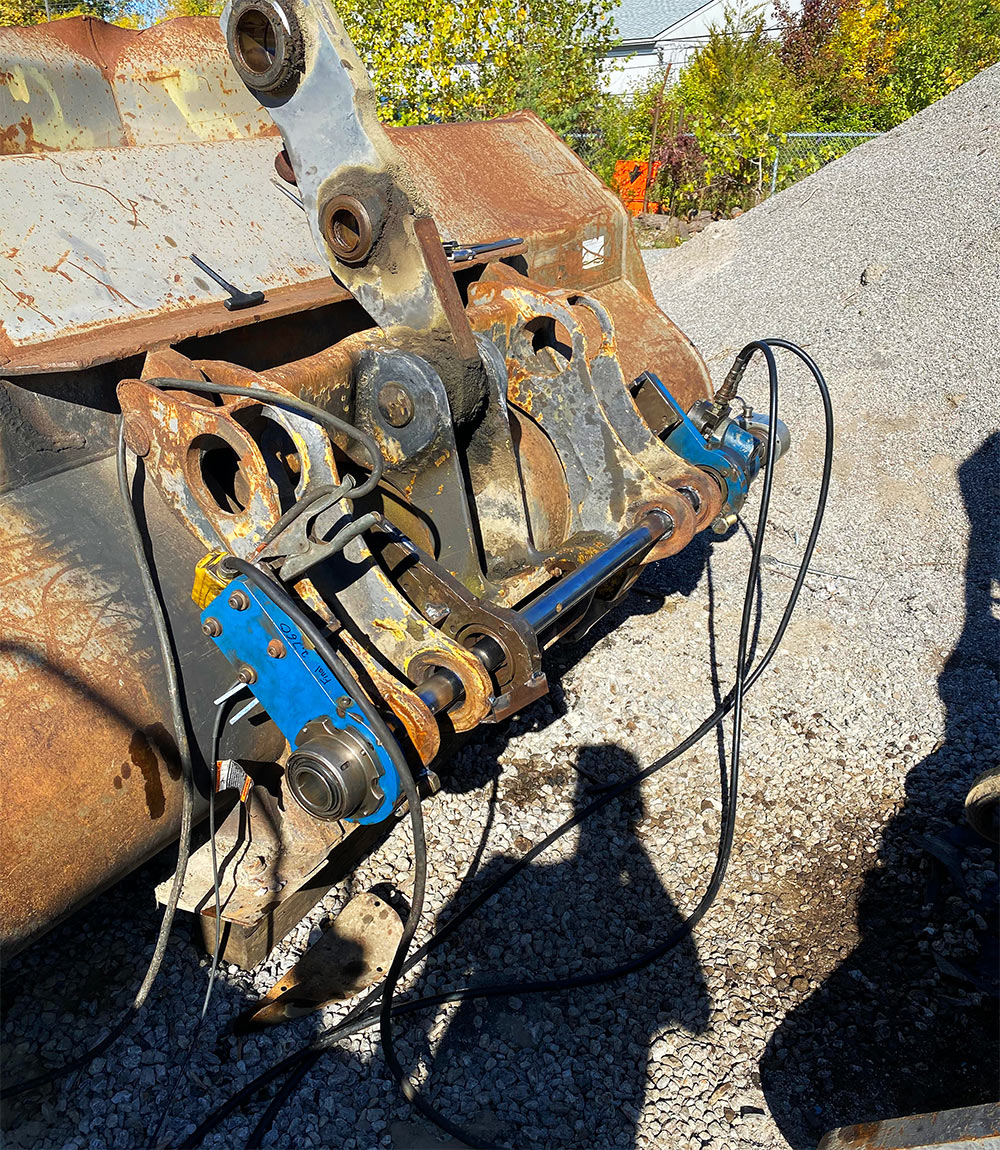

Detroit Equipment performs, mobile line boring, heavy equipment repair, hydraulic services, and field service of all heavy equipment brands.

Please reach out to Mario at (313) 920-1810 for any inquiries.

Mobile Line Boring Services For Engines: What It Is and How It Can Help You

Are you stuck in a rut? Wondering how to get your engine back in gear? Maybe it’s time to revamp your operating procedures and develop an engine revamp plan. Rebuilding your engine might seem daunting, but the good news is that the engine rebuild can be done without investing in a lot of costly machinery. It’s much easier than you think. Revamping your engine means completely changing the way it works, which can be as simple as replacing worn parts with new ones, or as complex as getting it rebuilt from the ground up. There are many different revamping an engine, but the most common are horizontal and vertical line boring. Horizontal line boring services for engines is a process that is used to bore a new horizontal axis (also known as a horizontal axis). Engines that are horizontal axis incline at a specific angle. When a horizontal axis engine is not operated at the correct angle, it can lead to many problems, including vibrations, uneven running, and even damage. A vertical axis is an engine mounted perpendicular to the horizontal axis. Often, engines are horizontal axis engines that have been modified to have a vertical axis. Instead of turning, a vertical axis engine moves in one direction while turning. If you want to revamp your engine, check out the following list of services and see which one appeals to you the most.

What is a Mobile Line Boring Service?

A line boring service is a machine that bores a new horizontal axis, also known as a boring bar. A boring bar is usually used in place of a boring machine when revamping a horizontal-axis engine. The boring bar creates a new horizontal axis by drilling a hole into an existing structure, usually the foundation or the wall of a building.

The Theory Behind Mobile Line Boring

There are two main types of boring line services: open-ended and shut-down.

Open-ended boring services are intended for construction, whereas shut-down boring services are used for manufacturing. However, both share the same purpose: to bore a new horizontal axis in a building. Open-ended boring services create a new horizontal axis from the inside of a building. This method is often used for construction projects as it eliminates the need to excavate the ground. The boring services are used to remove the structure that is being renovated and then drill a new horizontal axis.

Shut-down boring services work in reverse. First, an existing horizontal axis is drilled to create a template for the boring service. The boring service is then used to drill a new horizontal axis through the building, dismantling and then reinstalling

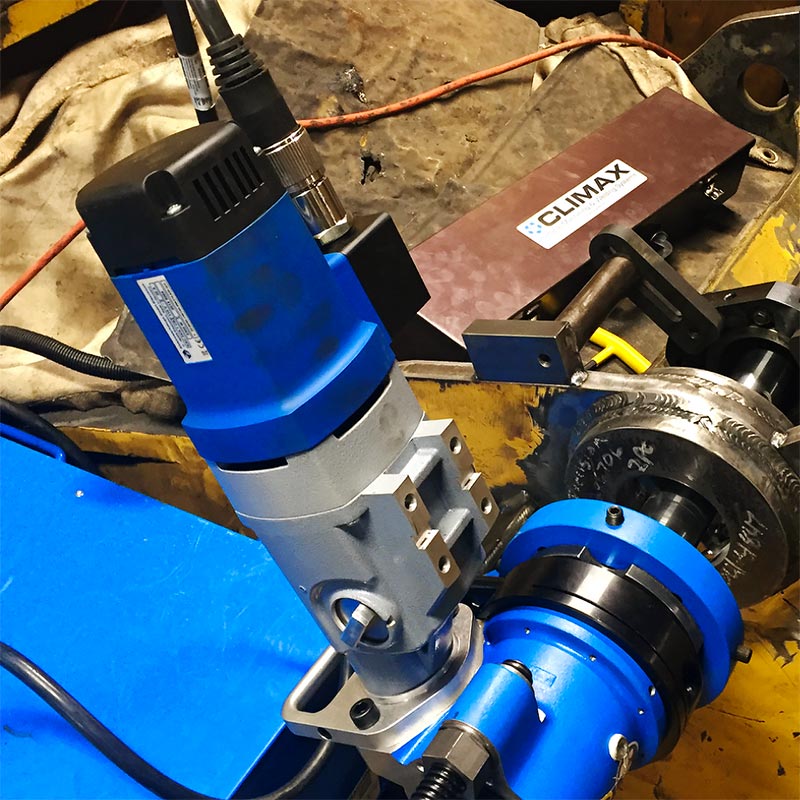

Mobile line boring is done in the field, on-site at your job site..

Different Types of Line Boring Services

Open-ended boring – These services drill a new horizontal axis from the inside of the building out. They are often used for construction projects and can be very cost-effective.

Shallow-diameter boring – Shallow-diameter boring services are used for drilling a new horizontal axis that is no more than 10 meters deep. This type of service is popular in Europe as it allows for large buildings to be renovated.

Conventional boring – Conventional boring services are used to drill a new horizontal axis between 11 and 25 meters deep. They are also found in Europe and are popular because of their simplicity.

Underground boring – Underground boring services are used to drill a new horizontal axis deeper than 25 meters. The reason why they are called confidential boring services is that they are drilled as an underground operation.

Shield boring services – Shield boring services are used to bore a new horizontal axis with a circular shape, usually at the center of a building.

How Line Boring Works

A boring service consists of a boring bar with a drill on one end and an axis with cutters. The boring bar is placed on the existing horizontal axis, and the drill is used to drill a new axis. When the boring service is in motion, the drill removes material from the vertical axis, leaving a cutting edge on the vertical axis. As the boring service bores down, the new axis is cut, and the horizontal axis is drilled out from the other side of the vertical axis. The cutters on the boring service are typically set at a 45-degree angle from the horizontal axis to maximize the length of the cutting edge. This allows the blades to cut the vertical axis as they are rotated.

Pros of Using a Line Boring

- No Excavation and Drilling – As mentioned above, open-ended boring services do not require excavation. These services can start drilling as soon as the horizontal axis is enlarged.

- No Damage to Walls, Floors, or Ceilings – Another advantage of using an open-ended boring service is that there is no damage to walls, floors, or ceilings.

- No Special Equipment – There are no unique pieces of equipment required to use an open-ended boring service. The boring service and the boring bar are usually portable, which means they can be used anywhere.

- No Special Machine Shop – A particular machine shop is not required to use an open-ended boring service. It can be done in any shop with a drill press and a boring bar.

- No Special Operations – Unlike shut-down boring services, open-ended boring services do not require any special operations to create a new horizontal axis.

Cons of using a Line Boring

- Expensive and Time-Consuming – These services can be expensive and time-consuming, so they are best suited for projects that require a new horizontal axis.

- Large Scope of Work – The scope of work for a line boring service is usually enormous and may include excavating the ground, drilling the horizontal axis, and installing the new horizontal axis.

- Complex Geometry – The geometry of the building is complex, which means the building will have many angles. This may lead to vibration, uneven ground, and structural instability in the building.

- Large Area – The building area that will be bored out is usually significant. This means that the boring service will need to be significant as well. – No Return – Once the new horizontal axis is installed, there is no way to reverse the process without drilling through the building.

- No Guarantee – Most boring services come with a warranty that guarantees the work, but there is no guarantee that the new horizontal axis will stand the test of time.

- Can be Expensive and Time-Consuming – As mentioned above, open-ended boring services can be expensive and time-consuming. This makes them best suited for large-scoped projects that require a new horizontal axis.

- Large Scope of Work – The scope of work for an open-ended boring service is usually enormous. It may include excavating the ground, drilling the horizontal axis, and installing the new horizontal axis.

What We Know

Revamping your engine might seem daunting, but the good news is that it can be done without investing in a lot of costly machinery. It’s much easier than you think. These are the major pros and cons of using a line boring service: Pros of using a line boring service – No Excavation and Drilling – As mentioned above, open-ended boring services do not require excavation. These services can start drilling as soon as the horizontal axis is enlarged. – No Damage to Walls, Floors, or Ceilings – Another advantage of using an open-ended boring service is that there is no damage to walls, floors, or ceilings. – No Special Equipment – There are no special pieces of equipment required to use an open-ended boring service. The boring service and the boring bar are usually portable, which means they can be used anywhere. – No Special Machine Shop – A particular machine shop is not required to use an open-ended boring service. It can be done in any shop with a drill press and a boring bar. – No Special Operations – Unlike shut-down boring services, open-ended boring services do not require any special operations to create a new horizontal axis. – No Guarantee – Most boring services come with a warranty that guarantees the work, but there is no guarantee that the new horizontal axis will stand the test of time. – Expensive and Time-Consuming – As mentioned above, open-ended boring services can be expensive and time-consuming. This makes them best suited for large-scoped projects that require a new horizontal axis.

Detroit Equipment performs mobile line boring, heavy equipment repair, hydraulic services, electrical service, and field service of all heavy equipment brands.

Please reach out to Mario at (313) 920-1810 for any inquiries.